BraunAbility Q-Series

Almost all lifts on the market today follow a common industry standard set by BraunAbility close to 40 years ago. Over that time our lifts have earned the reputation of being reliable workhorses. However, inboard lifts also ride inside the cabin and honestly, sometimes they're not the best passengers. They can rattle. They can look ugly in nice vans. They can even shift and sway under load while in use.

Having a lift that goes up and down is one thing. We set out to reinvent the wheelchair lift to match the premium experience of modern vehicles. By combining our four decades of experience with human-centered design processes we now proudly present our new BraunAbility Q-Series inboard lifts. The reliability and robustness synonymous with BraunAbility together with a smart design that excels above all others in three dimensions: quiet while driving, structural rigidity and design aesthetics.

The Q-Series lifts are as quiet as they get. In a blind test you wouldn't even be able to hear the difference between an empty van and one with a Q-Series lift installed.

The rigidity of the platform is a major factor in the user experience. Nothing is as scary as riding on a floppy platform. These lifts are so rigid, we dare say they're the only lifts that are designed for having an attendant riding in the outer corner of the platform together with the wheelchair user. In plain numbers that's about 300 percent more rigid than any lift we’ve seen.

One thing you'll notice about a Q-Series lift is that it's not only pleasant to look at, it's filled with clever solutions for what used to be major or minor annoyances of yesteryear's lifts.

It's a well-known fact that a stowed wheelchair lift in the back of the van can clank, rattle and clonk to the point of driving anyone inside insane. By enlisting Professor Mark French, acoustics expert at the prestigious Purdue University in Indiana, we set out to silence the lift once and for all. The Q-Series lifts are oh so quiet. They are actually indistinguishable from the noise in an empty van.

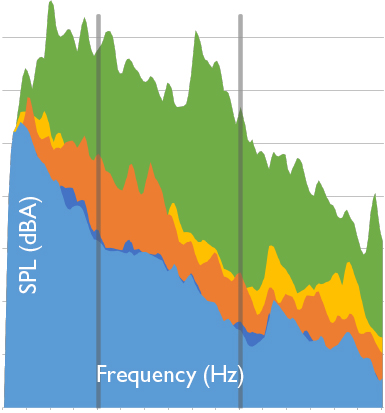

Even when visualising the noise in the form of a frequency spectrum plot, you will not be able to tell whether the van is empty or if it has a Q-Series lift installed. A common way to measure loudness is by the A weighted decibel level or dBA. When we measured a number of our competitors, they were 5-19 dBA louder than the empty chassis. Since dBA is not a linear scale, every increase of 10 dBA is generally perceived to be twice as loud. So an increase of 5-19 dBA means that competitive lifts raised the ambient noise to almost four times the normal volume of the interior.

Imagine that, a noise four times louder than anything already in your vehicle. Gives you a headache just thinking about it.

| Empty van | dBA | Loudness |

| BraunAbility Q-Series lift | +0 dBA | 0% |

| Competitor A | +5 dBA | ~ 40% |

| Competitor B | +6 dBA | ~ 50% |

| Competitor C | +19 dBA | ~ 400% |

Noise suppression

So how did we silence the Q-Series lifts? Well, we didn't leave anything to chance, that's for sure. They are packed with noise suppression features and a unique feature called Auto-Tite™.

Auto-Tite™

All hydraulics lose pressure over time, and the problem with this in a wheelchair lift is that the lift will slowly acquire the ability to rattle. For each ignition cycle, Auto-Tite™ will check the pressure of the hydraulics, ensure the doors are closed, wait for the engine to be started, and if necessary start the pump making sure the lift is stowed up tight.

Rattle and drum

The baseplate and inboard barrier used to be sources of noise. We've silenced them once and for all.

Lean on this

Noise suppression details can be found almost anywhere, like these rubber bumpers making sure the platform is quiet when stowed.

As nice as an ultra-light lift sounds, weight reductions can come at a high cost to safety, rigidity and reliability. We don't believe in gambling with these factors just so we get to call it: "World's lightest lift!". Instead we opted for reducing the weight as much as we could without any negative trade off.

The Q-Series wheelchair lifts weigh in at about 150 kg. Compared to our previous models, we've cut weight by roughly 10 %. However, it's also 300 % more rigid than any other lift we’ve tested. That rigidity is something you will feel when riding on the lift. It will feel safe and reliable.

In engineer technobabble weight reduction can be achieved with one or more of the three G's: Grade, Gauge and Geometry. In plain English that is the material, the thickness of the material and the shape of the structure.

Grade

Aluminium is usually a material of choice when cutting weight. But it’s prone to fatigue cracking, something probably familiar to anyone who has used an aluminium lift for any longer duration of time. It also causes rigidity problems.

Since our aim is to provide reliable accessibility which is safe and secure for the long haul, we decided to go for high-strength steel.

Gauge

A thinner material means a lighter lift, but thinner isn’t always better. Increased point loads on bearings will reduce their lifespan and rotational forces from hinge pins will inevitably cause headaches. The latter being one of the most common reasons for lift failure in the industry.

By adding surface area around the bearings, we’ve managed to minimise point loads. As for the hinge pins, we call ours, strapped hinge pins. The strap reaches out from the centre of the pin to gain leverage against rotational forces. Quite clever if we may say so ourselves.

Geometry

The shape of the structure can make a big difference. A good geometry will be more material efficient and provide better structural stability. By moving away from the industry standard geometry in the lower parallel arms, we've greatly increased the rigidity of the platform. It's actually 300% more rigid than any other lift tested.

We say it's the only lift designed to have the attendant riding in the outer corner of the platform together with the wheelchair user.

The normal service life of a wheelchair lift is usually less than 10,000 cycles. For decades all BraunAbility inboard lifts have been tested to meet our internal requirement of 32,000 cycles, and the Q-Series is no exception. In addition to this we have also tried to closely simulate real-world conditions. We've stressed the base plate welds to a maximum by performing cycle testing on both rigid and flexible floors.

Cycle test approved

Climate test approved

EMC test approved

Crash test approved

Most people tend to think of design as a way to make something look good, but design is so much more than that. It's about interaction with the user, the service and maintenance technician or just anyone in the vicinity of the product.

Together with Professor Steve Visser at Purdue University in Indiana, we gave the Q-Series lifts a distinct curved design language with a modern look as well as a number of clever features that just makes life simpler.

Illumination

The Q-Series platform will be hard to miss even when deployed low to the ground in a dark parking lot. We’ve added light strips along both the inside and outside of the platform, making it highly visible to anyone in its vicinity.

Contrary to standard platform lights mounted on the vertical channel, it also keeps the lights out of the user’s face and ensures that the user won't block the light from reaching the platform.

Pendant

The new pendant is an ergonomically intuitive way to control the lift. It sits in its holder on the pump module. Turn the lift on and the pendant lights up, making it easy to find even in low light. The pendant has a single rocker switch, push down and the lift deploys and lowers down. Press up and the lift goes up and stows.

Compatible with our Remote App

Pump module

The curved design is reflected in the pump module as well. The cover is held down by magnets and can be removed without using a screwdriver. As the pump module is often located close to the vehicle walls, we've made sure that access to some of the more common service parts is possible without having to take the lift out of the vehicle.

Durability

To make sure your BraunAbility wheelchair lift stays as beautiful as the day you bought it, we have added a number of features to areas exposed to the wear and tear of daily usage. For instance, the parts of the lift that comes in contact with the ground are now made of rubber and stainless steel. This will prevent rust and unsightly scratches from staring back at you as soon as you open the vehicle door. When these “bumpers” eventually wear out, they’re easy to replace.

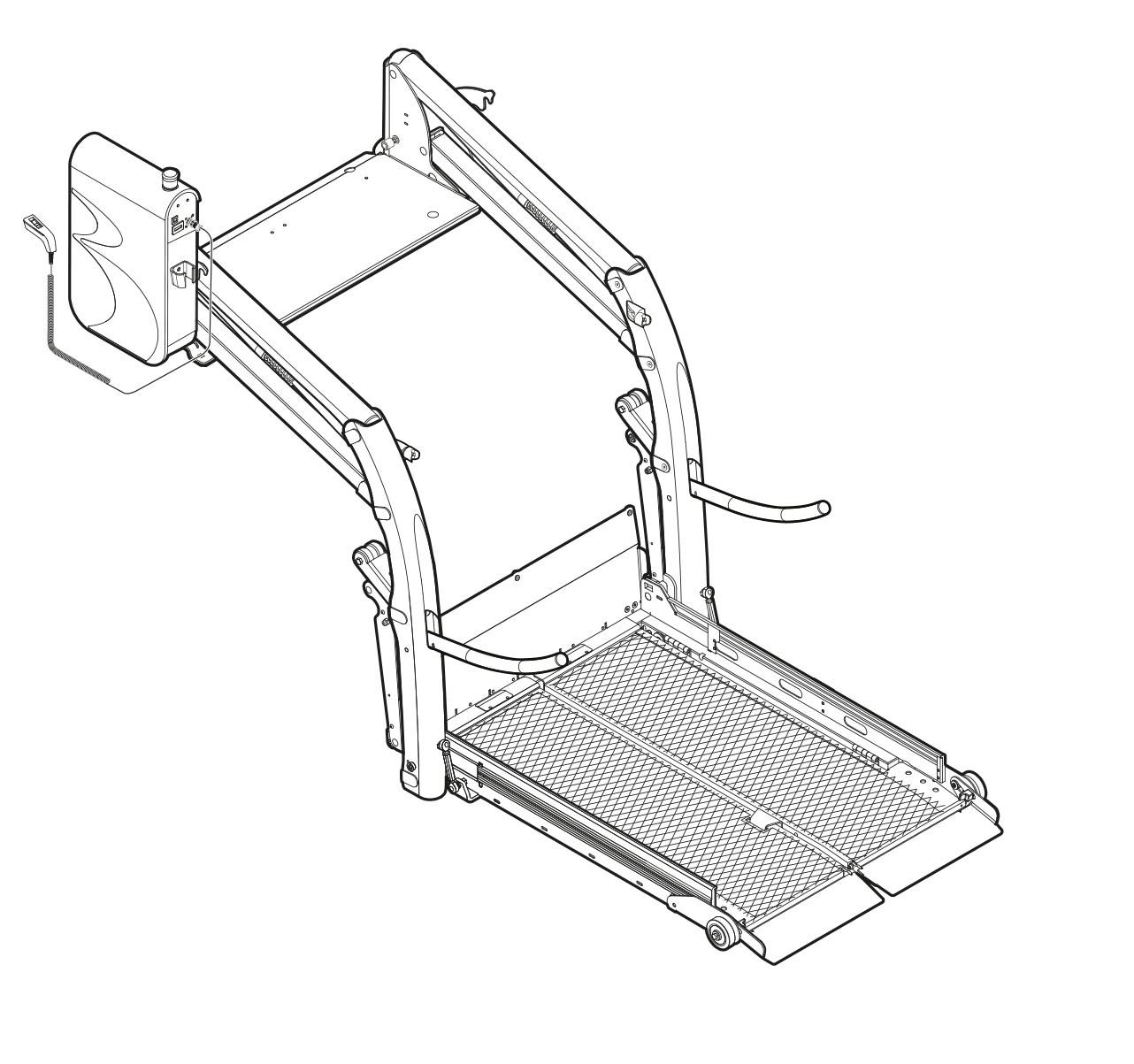

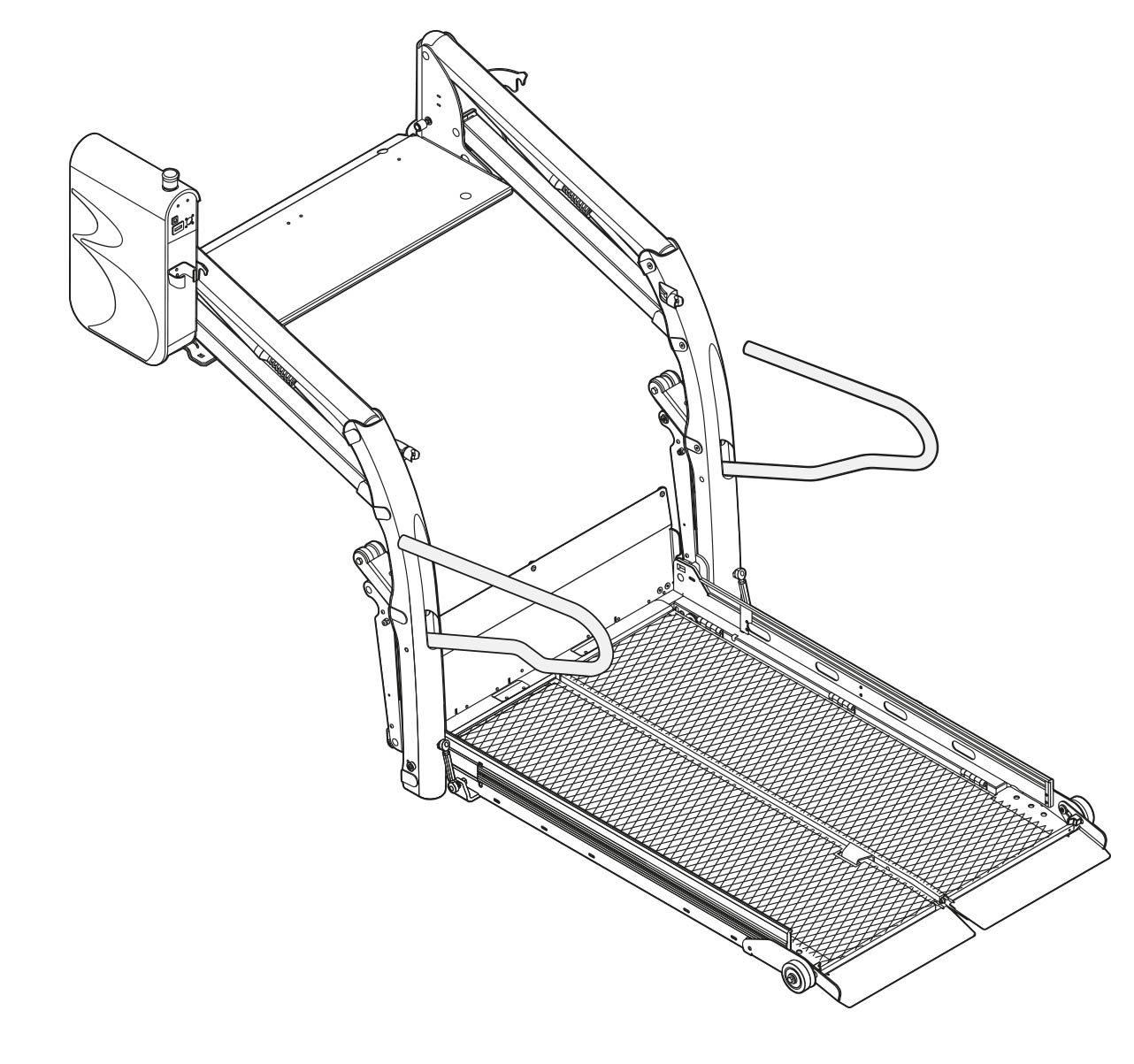

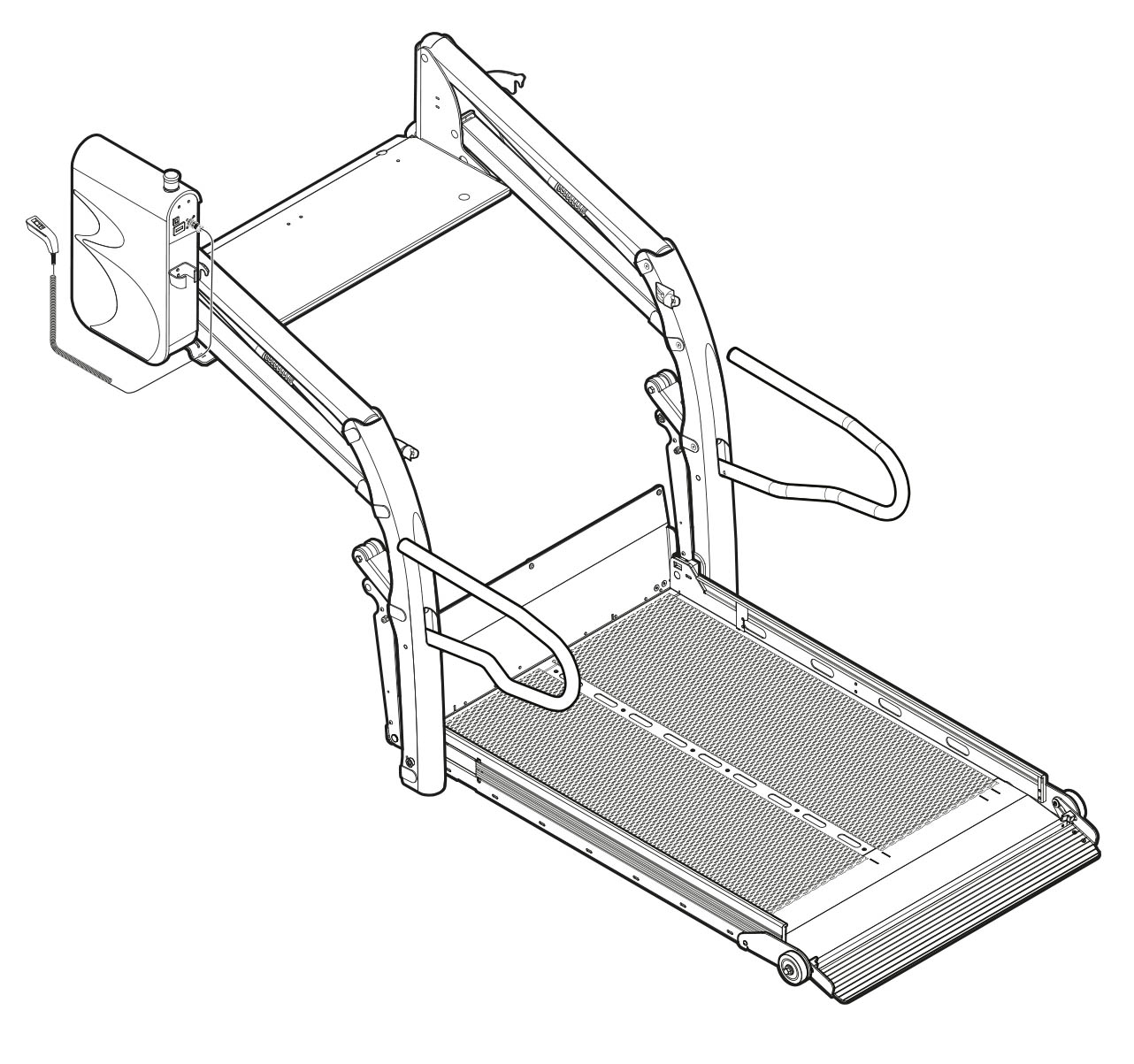

The Q-Series wheelchair lifts come in two different platform types, Split and Solid. Both are well proven platform types that have their own benefits. Choose the platform type that best suits your application.

The vehicle floor to lift threshold is the lowest on the market making loading easy and reduces the risk of tripping to a minimum. The split platform is designed for side and rear door installation.

Dimensions

| Platform width | 740 mm |

| Platform length | 1070 mm |

| Overall height | 1152 mm |

| Overall width | 1114 mm |

| Overall depth | 518 mm |

| Floor to ground | 800 mm |

| Required door width | 985 mm |

| Required door height | 1185 mm |

Dimensions

| Platform width | 860 mm |

| Platform length | 1320 mm |

| Overall height | 1406 mm |

| Overall width | 1245 mm |

| Overall depth | 580 mm |

| Floor to ground | 800 mm |

| Required door width | 1165 mm |

| Required door height | 1435 mm |

Weights

| Weight capacity | 400 kg |

| Unit weight | 139 kg |

| Shipping weight | 164 kg |

Weights

| Weight capacity | 400 kg |

| Unit weight | 156 kg |

| Shipping weight | 181 kg |

Dimensions

| Platform width | 860 mm |

| Platform length | 1320 mm |

| Overall height | 1413 mm |

| Overall width | 1215 mm |

| Overall depth | 412 mm |

| Floor to ground | 800 mm |

| Required door width | 1165 mm |

| Required door height | 1435 mm |

Weights

| Weight capacity | 400 kg |

| Unit weight | 143 kg |

| Shipping weight | 168 kg |

Testing

| Cycle test approved (32,000) | |

| Crash test approved | |

| Climate test approved | |

| EMC test approved |

Standards

| EN 1756 compliant | |

| ECE R-10 compliant | |

| REACH compliant | |

| GADSL compliant | |

| RoHS compliant | |

| 3TG compliant |

Compatible with our Remote App