BraunAbility A-Series

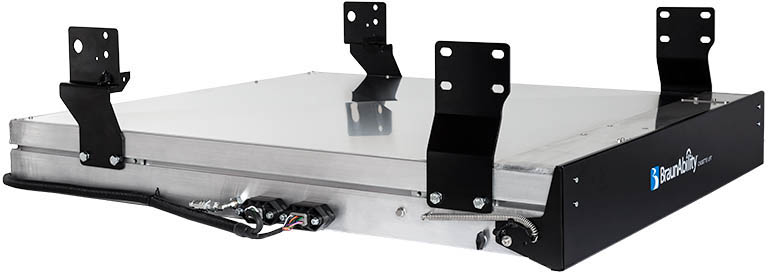

A cassette lift for public transport minibuses.

The BraunAbility A-series lift was developed in Europe for the European public transport market. Key focus lies on quick installation, low weight, reliability and ease of service.

The cassette form factor has its benefits. For one, since it is mounted under the floor, it allows for maximum flexibility in floor planning. In the event of an emergency, another type of lift could be a potential obstruction to the only exit.

At 124 kg, 149 kg fitted, it’s the lightest lift on the market that can do a stable lift of 350 kg. In other words, it has the lowest weight to lift capacity which also makes it the green choice in terms of fuel economy. Depending on the vehicle, a lightweight lift might be just the trick to get that one extra seat in - and still comply with regulations.

We wanted our lift to take everyone into consideration. From the converter and the specifier, to the driver and the passenger. We've put it through tests, made it lightweight, designed it to be easy to operate and for the passenger to feel safe using the lift.

Mounting brackets that utilise the chassis existing hole pattern, for all major brands. Quick connections for fluids and power. A pump module designed to take up as little volume as possible.

These are some of the features we've come up with to make the installation process quick and to provide a space efficient result.

For us, a reliable lift is one that will do its job regardless if it is used several times a day or just once a year. It should be able to withstand the wear and tear that comes with public transport; dirt, water, extreme temperatures as well as the passage of time.

Salt spray test

According to ASTM B117-11

Climate test

Multiple full cycle tests in -15°C and +60°C

Cycle test

32,000 cycles at maximum load

EMC test

According to ECE-R10

The BraunAbility A-series lift complies with the EN1756 standard.

We've focused on making our lift as light and as strong as possible, but why? Well, when you put a significant amount of weight behind the rear wheel axle it changes how the vehicle behaves, quite a lot. A heavy rear load could cause oversteering and other issues that makes driving the vehicle an unnerving experience.

Also, depending on the vehicle, a lightweight lift might be just the trick to get that one extra seat in - and still comply with regulations.

Another benefit of low weight is of course fuel consumption. Not just from an economic perspective, but even more important, keeping the environmental impact down to an absolute minimum.

The comparison shows lifting capacity divided by fitted weight. The data was acquired in April 2016 from the marketing material of each respective manufacturer.

Design

Grit and grime in mechanical devices can be just as bad as the proverbial spanner in the cogs. But you can’t really ask your passengers to thoroughly clean their wheels each time you intend to use the lift. We’ve designed and tested our A-series lift to minimize the effects of dirt in the machinery. It should work even if you were to shovel gravel into its innards, figuratively speaking.

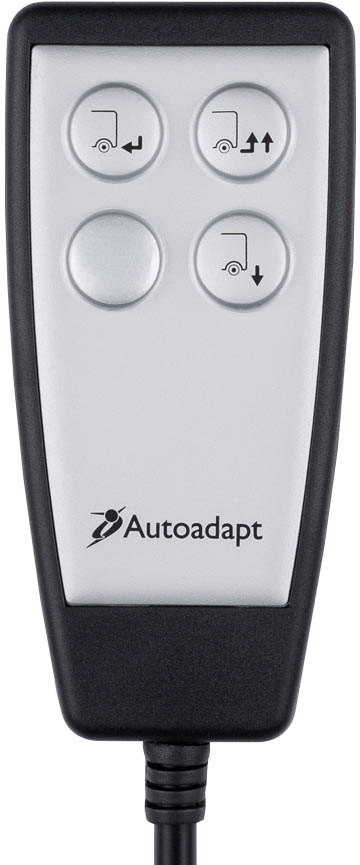

Remote

For simplicity only three buttons are used to control the lift. Clear visuals on each button indicates its function(s).

One button to stow the lift.

One button to deploy and raise the lift.

One button to lower the lift.

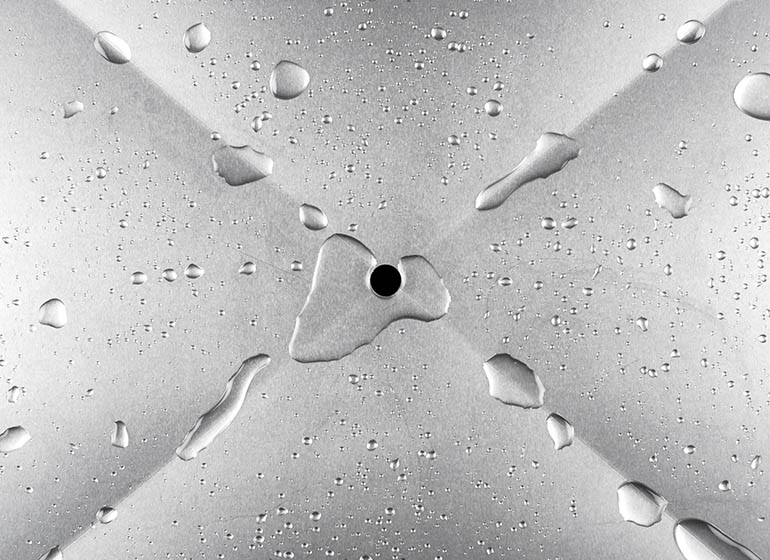

Anti-slip surface

Anti-slip surface on the platform and bridge plate, for the safety of both wheelchair users and standees.

Sturdy handrails

Highly visible and sturdy handrails, that user and operator can rely on.

Manual bridge plate

Unfold manually when the lift is deployed and fold back manually when stowing the lift. No handling needed in between.

Smooth and silent in operation

Providing a comfortable experience for user and operator.

Taking into account that wiring and hydraulics are similar in all cassette lifts, we dare boast that no other lift is as quick to install as ours. It’s all done in three easy steps.

.

1. Vehicle specific mounting brackets

Each vehicle specific mounting bracket uses the vehicle’s existing hole pattern. This means that you don’t need to drill holes or do complex measuring. Simply find the corresponding holes and bolt the brackets into place.

2. Purpose designed packaging

The A-series lift itself arrives on a pallet with wooden tansport brackets. Remove the transport brackets, then use a forklift to lift the pallet and position the lift between the mounting brackets. In order to get as close as possible to the rear axle, the lift is placed slightly off centre on the pallet.

3. Adjust and tighten

When the lift is in the correct position between the mounting brackets, insert and tighten the bolts in the mounting brackets and their counterparts found in the groove along the cassette side. This design makes it possible to easily adjust the position of the lift if desired. In vehicle models where the wheel axis allows, the lift can either be installed flush with the back of the vehicle or protruding, in order to be used as a step.

Compatibility

For quick and easy installation, we have mounting brackets for a majority of the minibuses available today. Our mounting brackets use the existing hole pattern in each specific chassis. In other words, you do not have to drill any holes in order to attach our cassette lift to the vehicle.

To ensure that the lift is level, the inner most bracket hole is circular and works as a hinge, whilst the others are slotted, allowing adjustment of the lift angle.

Mounting brackets and installation quick guides available for:

Mercedes-Benz, Volkswagen, Ford, Peugeot, Fiat, Citroën, Iveco, Renault, Opel, Nissan.

One of the best reasons to use a A-series lift instead of any other type of lift is that you don’t have to sacrifice the number of seats to install a lift. However the pump module usually takes at least one seat. We designed our pump module to be as thin as possible and to be partially hidden behind the panel of the vehicle, so that it takes up even less space.

Within these walls

Another perk that comes with placing the pump module partly hidden in the vehicle’s wall is that it can be placed where space and seating efficiency as well as usage efficiency is at an optimum level – in the back close to the lift. Quite convenient if the driver needs to manually operate the lift in the event of a power failure in the vehicle.

Is your lift damaged? A spare lift can easily replace the damaged one thanks to the mounting bracket and quick release connections for the fluids and electronics. Your vehicle could be back on the road within the hour. The A-series lift has been designed to use only relays and switches, most of them so common, you can find them at your local petrol station.

Italy

"It may look simple, but you can tell that there is a lot of thought behind it. Actually, I’m really impressed with how quick and simple they made the installation process of this lift. It only took a fraction of the time to install compared with the other cassette lifts we use in our vehicles."

Luca Quintavalli

CEO & Owner, Olmedo Special Vehicles S.p.A

Sweden

"I have 13 years behind the wheel as a bus driver for passengers seated in wheelchairs. On a normal day, I'd say that I do maybe 18-20 runs, using the lift twice as much. In my opinion it's a really good lift. It's easy to use and I can rely on it to lift me and my passengers safely into the bus each and every time. Perhaps my favourite part is the fact that it is easy on the body, even though there are some parts you have to do manually, I don't really do any heavy lifting at all."

Carina Tångring Petterson

Bus driver, Aros Buss

Spain

Scotland

"It’s working well for the work we do, it’s easier to use than the other models we have and not as heavy. We have had no problems with this lift and would be happy to use this model when any of our other tail-lifts need to be replaced."

Margaret Urie

Transport Co-ordinator, South West Community Transport

Dimensions

| Length | 1220 mm |

| Width | 1050 mm |

| Height | 140 mm |

| Platform length | 1225-1360 mm |

| Platform width | 800 mm |

| Minimum door width | 820 mm |

| Minimum overlap | 20 mm |

Performance

| Floor to ground | 1075 mm |

| Maximum travel up | 430 mm |

| Minimum travel up | 130 mm |

| Maximum travel down | 645 mm |

Noise level

| During use | < 70 dB |

Weights

| Weight capacity | 350 kg |

| Cassette weight | 124 kg |

| Fitted weight | 149 kg |

| Shipping weight | 168 kg |

Power

| Voltage | 12 V |

| Current | 80 A |

Testing

| Cycle test approved (32,000) | |

| Salt spray test approved | |

| EMC test approved | |

| E5 Type approved | |

| Climate test approved |

Standards

| EN 1756 compliant | |

| ASTM B117-11 compliant | |

| ECE R-10 compliant |